© 2023 Kreativa. All rights reserved. Powered by JoomShaper

Wood that Can be Beat: Fijian Barkcloth Beaters

|

| Barkcloth Beater (Ike), 19th Century Viti Levu, Fiji, Polynesia Wood; 10 ¼ x 2 5/16 x 2 1/8 in. 2019.20.1 Bowers Museum Purchase |

March to the Beat of your Own Beater

Whether made from the sheared wool of adorably cloud-like animals, pulled from cotton plants or spun from the gossamer silk of worms; textiles are made with a variety of methods throughout the world. Across Oceania, cloth is made with a rather unlikely medium: tree bark. Properly manipulated by being repeatedly pounded until it has the consistency of fabric, the massive swaths of beautiful cloth were traditionally used to decorate homes, be shaped into skirts and articles of clothing and presented as gifts. Much of the history and usage of these textiles is discussed in Fibers of History: Tongan Tapa Cloths, but this post—rather than focusing on the cloth—looks closely at a recently acquired Fijian barkcloth beater or ike and the larger context of how these textiles are made in Fiji.

|

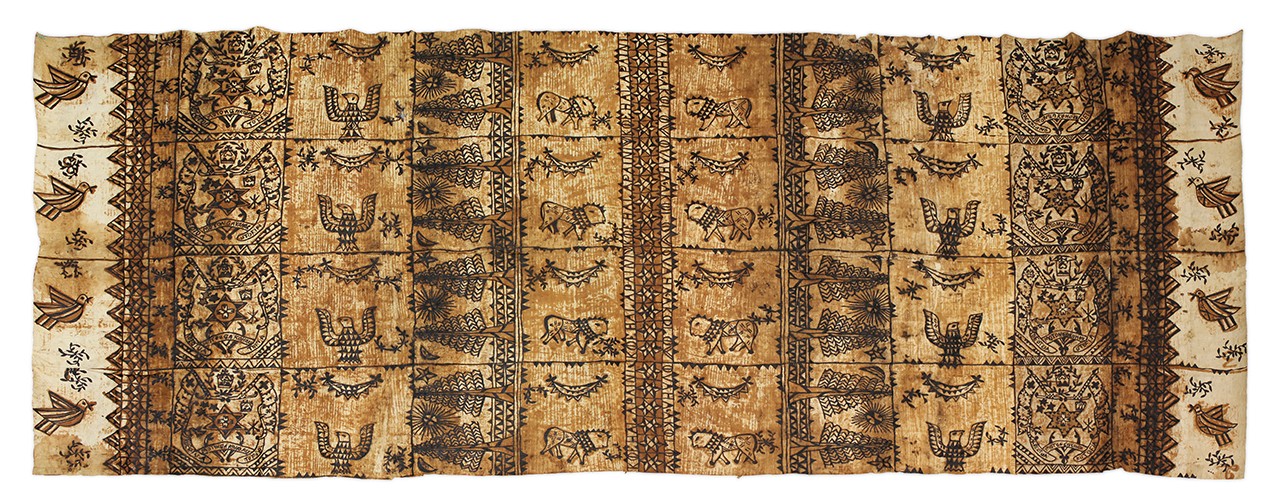

| Tapa Cloth (Masi Kesa), late 20th Century Mrs. Ropate (Fijian); Lau Group, Lau Province, Fiji, Melanesia Bark and pigment; 72 3/8 x 108 in. 2003.7.9 Bowers Museum Purchase |

From Twig to Tapa

The process of creating bark cloth begins with the tree from which barkcloth is made. Though originally breadfruit and ficus were used in Polynesia, over time production shifted to almost exclusively rely on the soft wood of the paper mulberry tree. Women cultivate these trees in plantations where they are guarded from the elements and animals which would naturally eat the young saplings. The trees also need to be closely monitored to ensure that none of the sprigs grow into full branches which would create holes in the eventual bark. Traditionally the trees would be harvested at night during the appropriate part of the lunar cycle when they naturally retain the most moisture. An average tree eventually produces about 12 square feet of cloth. To put this in context, barkcloths can regularly be up to 150 feet long and 15 feet wide, with a historic record of a 540-foot-long cloth.

|

| Taking a break in barkcloth beating in Nuku'alofa, Tonga. Public domain. |

The Bast Textiles in Town

After soaking the wood in saltwater to further soften it, women next need to strip the bark from the harvested trees. This is done by creating a small incision in the stalk and then peeling off the outer layer of bark. It is delicate work, as mistakes made during this process can ruin sections of would-be barkcloth. If it is done properly the outer layer of bark is removed and the inner bark is pulled in strips. Women hold these strips against a long wooden anvil or yatau and then use ike to repeatedly pound the bast until it has been flattened out. The reason why mulberry is principally used—aside from growing quickly and being a soft, malleable wood—is that the fibers naturally adhere to one another when they are wetted, meaning that producing larger swaths of cloth is as easy as putting two pieces together, wetting them and then pounding them until they are one. The process of applying designs is equally complicated, and though Fijian masi barkcloths include more techniques than Tongan examples many of the processes are similar and described in Fibers of History: Tongan Tapa Cloths.

|

| Tapa Cloth (Ngata), 20th Century Tongan culture; Tonga, Polynesia Pounded tree bark and pigment; 78 x 152 in. 93.18.1 Donated by Jeff and Laura Blackie |

All Things Carved

Beaters are made from a tough pine found throughout much of Oceania which is colloquially called ironwood. Rather than being made by the women who cultivate and later create barkcloths, on Fiji the beaters are carved by the same male woodworkers who craft clubs—it is the reason why at least one side of many four-sided beaters is sometimes carved with the intricate incisions seen on Fijian clubs.

|

| Alternate view of 2019.20.1 Bowers Museum Purchase |

Things Get ‘Round

Most Polynesian beaters are four-sided, with three of the sides grooved to better-pound the bast and with the last side flattened to create a smooth final texture for the textile. However, this object is ovoid in shape, with grooves traveling all the way around the beater. Fiji was a meeting place for two of the major cultural super groupings in Oceania. Though most of Fiji’s inhabitants came from Melanesia, its proximity to Tonga and Samoa meant that there was significant trade and migration back and forth between the islands. The result is that more techniques are used to create and decorate barkcloth in Fiji than are used anywhere else in Polynesia. This holds true for ike styles as well. Along the coast the traditionally Tongan style of square-sectioned beater is used, but in the highlands of Fiji’s largest island, Viti Levu, this older style of rounded beater which originated in Melanesia was employed. Originally these beaters are carved to be perfectly round, but over time the repeated use of beating them into the wooden anvil over and over causes the side to get worn down. The concave indentations on the side of this beater might be explained by a convex yatau.

Text and images may be under copyright. Please contact Collection Department for permission to use. References are available on request. Information subject to change upon further research.

Comments